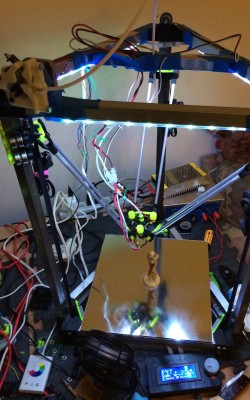

Meet the K03 first working prototype. It’s not as pretty as it could be due to all the blue tape at the top, but it works and it works well!

At this point I wouldn’t recommend anyone attempting to build this machine, despite my success with it. It has a few drawbacks which could be particularly daunting for anyone new to 3D printing. In particular – the roller mechanisms are slightly too heavy for the holding weight of powered off NEMA17 motors, which means that it MUST be homed before ANY move to avoid slamming the hotend into the print bed and cracking the effector. It’s also a little on the difficult side to assemble due to some of the blind nut-traps on the frame mounting portions.

To this end, I have a re-design of the carriages in progress to reduce the number of bearings and bolt hardware required to achieve linear motion along the steel tubing as well as some plans for a new tube mounting mechanism which will allow for easier assembly of the overall structure.

Unique Features

This printer uses tubing that can be found at any North American hardware chain – specifically steel and aluminum tubing. To that end, it also uses SAE hardware nearly exclusively, the exceptions being the extruder assembly which uses M3 bolts and the effector which is built around M4 hex-head bolts.

There are easier ways to achieve this mechanism, but if you’re near a Home Depot or a Canadian Tire, you can pick up the majority of the machine for cheap in a single trip.

Currently it uses 608ZZ bearings exclusively which are heavy, but are also very common and easy to obtain.

Building It

I won’t be posting any sort of build-guide for it at this time, nor a full parts list. Despite it being a working machine, I don’t recommend anyone build it at this time – I have a laundry list of improvements to make which will make it easier, cheaper and faster to build.

Where To Look at the Parts

You can find the machine on GitHub at https://github.com/novakanereprap/Kichesippi-03